Loading... Please wait...

Loading... Please wait...Categories

Recently added

Recently added

-

£1,500.00 (inc VAT) £1,250.00 (ex VAT)

-

£52.46 (inc VAT) £43.72 (ex VAT)

-

£57.12 (inc VAT) £47.60 (ex VAT)

-

-

£137.20 (inc VAT) £114.33 (ex VAT)

Our Newsletter

- Home

- Hire & Maintenance for Safety & Medical Equipment

- Safety Equipment Maintenance

- 'AGA' Mask & Demand valve, annual service

- Home

- Diving, Marine PPE & accessories

- 'AGA' Mask & Demand valve, annual service

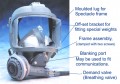

'AGA' Mask & Demand valve, annual service

Product Description

Send it back to us.

We clean it, fix it, record it and send it back to you; for confident, year-long, 'Safe breathing in all Environments'.

Proper Recording, Maintenance and Service of SCUBA, at least annually, is a legally binding duty up on professional divers and diving schools.

But some recreational divers (who are not so regulated) omit taking sensible safety measures with their life support equipment!

Recent increment in diving accidentals, has demonstrated that improper use of, or failed maintenance of diving equipment is a major factor.

We're not in the scare business but we strive to ensure divers are properly tutored to understand and carry out the necessities of keeping equipment safe and serviceable.

We are sometimes horrified by the condition of diving equipment, sent us for repair or assessment. Hoses, which, under pressure, reveal bubbles and bulges; metal components that are caked in corrosion and rubber parts that have long since perished and appear never to have been cleaned - are all part of a regrettably, regular picture, which is more characteristic of the diving sector than of industrial breathing equipment use where complicity with rules, regulations and preventative maintenance are well understood, statutory obligations.

Each mask and demand valve we service is logged and recorded for its performance and complicity with required routines.

A record is kept for at least five years, in accordance with the requirement of CoSHH Regulations, in Britain and parts replaced are carefully recorded on job sheets. Breathing Valves (Demand Valves) are tested for pneumatic performance, both statically and dynamically, so replicating representative approximation to EN250 type testing and complying with the requirements of BS4275.

In this way, our customers can be assured that equipment remains reliable, safe and serviceable. Supply hoses are tested at working pressures of 15 bar, to check for perforation or other defect and your kit is returned in the good, safe condition that we would expect from brand new kit.

The service price includes all O-rings, lubricants and inner mask disc replacement but major parts, if found due for replacement, are not included in the price. They are charged extra, at manufacturers' published prices.

Our repair and quality policy is stated under:

BREATHING APPARATUS MAINTENANCE:

Standard Charges for service to Interspiro (AGA) breathing valves and masks includes necessary replacement O-rings and replacement inner mask valve disks. Parts are changed, if found necessary after due examination and cleaning. Other parts requiring replacement, such as Valve seat cone and balancing diaphragm, are charged extra at published prices, or otherwise advised to the customer in advance.

CERTIFICATES OF TEST FOR B.A. & SCUBA INCORPORATING DEMAND VALVES, ARE BASED ON TESTS INDICATED BY THE MANUFACTURER’S PUBLISHED MANUALS AND OTHERWISE APPROXIMATE TO BS/EN TEST STANDARDS. IN PARTICULAR, BREATHING CHARACTERISTICS ARE TESTED TO PROVE COMPETENCE.

COSHH Regulations & Diving Regulations require a written record of Maintenance for all RPD, excepting disposable face-masks and equipment of simple design, to be kept for a minimum of five years, prior to disposal.

FOR BS 4667/-: POSITIVE PRESSURE BA SHALL MAINTAIN A PRESSURE ABOVE AMBIENT IN THE FACE MASK WHEN THE PEAK INSPIRATION RATE IS AT LEAST 250 LITRES PER MINUTE (> 4.1 LITRES/SEC) BUT NO HIGHER PRESSURE THAN 0.6 KPa AND EXHALATION PRESSURE SHALL NOT EXCEED 0.9 Kpa AT 250 LITRES/MIN NOR 0.6 Kpa DURING ANY EXHALATION.

NEGATIVE PRESSURE BA SHALL EXHIBIT EXHALATION CHARACTERISTICS IN THE SAME RANGE AND REQUIRE AN INHALATION OPERATING PRESSURE NO GREATER THAN 0.3KPa BELOW AMBIENT PRESSURE TO START THE AIR FLOW NOR SHALL THE PRESSURE REDUCE BY MORE THAN 0.5 Kpa BELOW AMBIENT WHEN THE PEAK BREATHING RATE IS 120 LITRES/MIN.

FOR Ens 136/137/402/250/-: SIMILAR TESTS WILL BE CONDUCTED BUT AT PEAK INHALATION AND EXHALATION RATES OF AT LEAST 300 LITRES/MIN. WHERE THE INHALATION PHASE MUST MAINTAIN POST ATMOSPHERIC PRESSURE BUT NO HIGHER THAN BY 0.4 Kpa AND THE MAXIMUM EXHALATION PRESSURES WILL BE: (OPENING PRESSURE) <0.6KPa, (@ 160 LITRES/MIN) <0.7 KPa and (@ 300 LITRES/MIN) <1.0 KPa.

BREATHING TESTS ARE CONDUCTED USING MANOMETERS ACCURATE TO +/- 0.01 kPa AND FLOW CHECK TESTS ACCURATE TO +/- 5%.

OTHER TESTS ACCORD WITH THE REQUIREMENTS OF THE APPROVED MANUALS, THOSE OF COSHH, DSEAR, MSB, & HSE Regulations.

Customer Compliance records (for monthly checks) can be maintained using our form H2/11/981, available in pads of 100. Our Test results are recorded and kept by us for dive years after the date of record.

Warranty Information

Find Similar Products by Category

Customers Who Viewed This Product Also Viewed

-

£855.60 (inc VAT) £713.00 (ex VAT)

-

£676.80 (inc VAT) £564.00 (ex VAT)

-

£50.03 (inc VAT) £41.69 (ex VAT)

-

£23.40 (inc VAT) £19.50 (ex VAT)