Loading... Please wait...

Loading... Please wait...Categories

Recently added

Recently added

-

£1,500.00 (inc VAT) £1,250.00 (ex VAT)

-

£52.46 (inc VAT) £43.72 (ex VAT)

-

£57.12 (inc VAT) £47.60 (ex VAT)

-

-

£137.20 (inc VAT) £114.33 (ex VAT)

Our Newsletter

- Home

- First Aid and Medical

- Oxygen decanting hose, 2 Metre, PI to BN, 230 bar

- Home

- Compressors and breathing gas equipment

- Oxygen decanting hose, 2 Metre, PI to BN, 230 bar

- Home

- Hire & Maintenance for Safety & Medical Equipment

- Oxygen decanting hose, 2 Metre, PI to BN, 230 bar

- Home

- Oxygen and Gas therapy kits

- Oxygen decanting hose, 2 Metre, PI to BN, 230 bar

Oxygen decanting hose, 2 Metre, PI to BN, 230 bar

Product Description

Oxygen Decanter Filling Assembly: part number: HO-O2HP-2M

User Instructions & Parts List

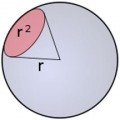

This assembly is designed to safely charge Oxygen cylinders fitted with either; UK Pin Index, medical Valves, or, with DIN477, breathing Apparatus Valves, approved for use with high oxygen partial pressure (up to 230 bar). The assembly components are pressure tested to 230 bar Oxygen partial pressure and to burst pressures exceeding 380 bar.

All high pressure seals are made from Viton® rubber, lightly lubricated with Fomblin YNX lubricant, or equivalent PTFE grease, suitable for oxygen service, up to 240 bar.Replacement seals must be of like standard and suitably fitted by a competent person. Likewise, its use must be only by people with appropriate experience and knowledge of Oxygen service equipment.

- Compressed gases are dangerous and compressed oxygen will set fire to many organic materials, at room temperature.

- Use high pressure equipment with caution. Do not allow pressure exposed components to be contaminated with dirt or grease.

- If contaminated, components must be carefully cleaned of all dirt and greasy contamination and washed of cleaning agents, before further use.

- Open Valves slowly, with caution. Operate Purge valve slowly, with caution.

Instructions for Use

- Carefully check that cylinder valves are clean and properly functional. Check both cylinders are within their respective test dates, clean and not contaminated with other gases or material.

- Connect the bull-nose end to the storage cylinder, from which gas will be drawn. A firm, hand tight fit is appropriate. Appropriate torque for hand tight connections is of the order of 10 to 15 NM. Do not overtighten. Bull-nose connections without an O-seal, need tightening to a torque of 20 to 40 NM, so that the brass faces will offer a gas tight connection.

- Ensure that the hose is laid so that no bend is tighter than 150 mm radius. The hose should be laid out, or, captive, in a cage, so that it can not ‘whip’ up and hit the operator, in the unlikely event of rupture. The confined lumen of the hose is designed to assist in limiting the contained volume and the charging rate, for safety reasons.

- Connect the Pin index adaptor (or the DIN 477 connection) to the recipient (closed) cylinder valve.

- Likewise, a firm, hand tight fit is appropriate. Where the Pin-indexed adaptor is used, ensure it is likewise tightened in to the DIN 477 connector.

- Using the correct cylinder keys, slowly ‘crack’ the donor cylinder valve, until its full pressure has registered on the gauge of the decanting assembly. Then open the valve sufficiently to allow charging progress – usually, about a half turn. Check that adequate pressure is available to re-fill the recipient cylinder. If any leaks are apparent, immediately close all valves and purge pressure from the decanting assembly, by depressing the purge button, adjacent to the gauge manifold. Then check all joints and seals where the leak has been apparent.

- Slowly open the recipient cylinder valve, so that gas passes in to it. Valves should not be opened to allow gas to pass at more than a rate of 100 litres (free gas delivery) per minute; otherwise there will be undue heat build up, due to adiabatic expansion. For guidance; a 2.4 litre cylinder (BOC, medical ‘D’ size) should fill from 0 to 137 bar no more quickly than over 3 ½ minutes.

- When the cylinder is full (noted by checking the gauge), close the recipient cylinder valve, then, close the storage cylinder valve. Purge gas completely from the charging assembly, by depressing the purge button carefully, keeping the hands and fingers away from the vent holes, opposite the purge button.

- Note that cylinders should not be filled to a greater pressure than indicated in the shoulder stamp marks, on the cylinder shoulder, near the maker’s identity marks. Most medical oxygen cylinders require a charge pressure of 137 bar.

- Release the recipient cylinder connection and mark the cylinder full, suitable for use.

- After use: release the charging assembly from the storage cylinder and cap its valve, to prevent dust and dirt building up. Store the charging assembly, clean and dry.

Note: Part number for replacement HP seals:

Bullnose: AP1409V, DIN477: AP1166V

|

Helios Item Part Number |

Spare Parts List |

Price, ex VAT |

|

|

HO-O2HP-2M |

2 Metre decanting hose assembly, with Purge valve and gauge. UK Bull nose to DIN 477 connector with Pin Index Oxygen adaptor. 230 bar WP. |

£297.50 |

|

|

HOHP022 |

Hose, 2 mtre. HP, PU/N6/Kevlar; 1/4 BSP BN SS nut, 2.2mm bore |

£89.90 |

|

|

1220 |

UK Bull Nose adaptor to G1/4 male |

£44.00 |

|

|

AP0306D/2 |

CHARGING CONNECTOR 232 BAR DIN DIN fitting with 1/4” BSP male outlet to fit 1/4” hose connector. |

£76.22 |

|

|

1336 |

Pin Index - Female DIN |

£65.00 |

|

Warranty Information

Find Similar Products by Category

Customers Who Viewed This Product Also Viewed

-

£0.00 (inc VAT) £0.00 (ex VAT)

-

£360.00 (inc VAT) £300.00 (ex VAT)

-

£0.00 (inc VAT) £0.00 (ex VAT)

-

£615.00 (inc VAT) £512.50 (ex VAT)